Hydrogen and Fuel Cells: Enhancing Warehouse Management Systems, Cutting Costs and Creating an Environmentally-Friendly Facility

Budgetary constraints and environmental impact have put increased pressure on businesses to reduce energy usage throughout their facilities. One area where businesses consume a significant amount of energy is in warehouses through HVAC, lighting and material handling equipment.

Plug Power remains focused on helping material handling centers be more efficient, productive and green through our GenKey complete hydrogen fuel cell solution. But of course, there’s a broader world of efficiency and energy consumption reduction that we fit into.

This was brought home in a recent article in DC Velocity on warehouse management systems (WMS) entitled “Four ways your WMS can cut costs and ‘green up’ your DC.” While distribution centers have long used WMS to plan the best routes for merchandise handling and distribution, the WMS is now helping businesses to leverage these efficiencies to reduce costs.

But here at Plug Power, we can see how the use of GenKey hydrogen and forklift fuel cell solutions can significantly enhance the impact made by your WMS. Here’s a summary of ways the article suggests companies can use the WMS to improve business metrics, with our input on how Plug Power can further enhance these suggestions.

Buy electricity at off-peak rates. Most businesses are either unaware that electricity companies vary rates throughout the day, or are unsure of how to adjust consumption to ensure the least amount of cost. The WMS can provide the data to participate in a demand response (DR) program that can help facilities reduce expenses, as utilities will actually pay large distribution centers to reduce energy usage during a “peak” energy event.

The GenKey enhancement: According to the article author, businesses pay up to 14 cents per kWh to charge up to 250 lift truck batteries. In addition, they are levied up to 10 cents per kWh for using brief spikes of power from the grid. These “peak demand” charges, which are designed to help share a local utility’s infrastructure and maintenance costs, can account for up to 70 percent of a large company’s electric bill.

Taking the demand response benefit a step further – fuel cell forklifts allow customers to remove the battery room and battery charging completely –eliminating this large source of energy usage. As a result, valuable real estate is not occupied by large battery rooms, and instead this space is used to generate revenue within the business, specifically moving more products with an efficient forklift fleet.

By eliminating the electricity costs associated with charging hundreds of lift truck batteries — coupled with peak demand charges — businesses can reclaim $75,000 to $225,000 per year, a significant financial savings, even for a large business.

Rein in forklift costs. Facilities can determine the most efficient forklift travel patterns or determine the minimum number of forklifts needed to complete daily tasks in order to reduce electricity or fuel costs.

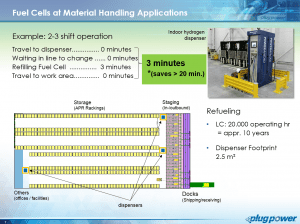

The GenKey enhancement: Keeping your trucks hard at work is top of mind for Plug Power, therefore we’ve designed a solution that allows you to strategically place refueling dispensers throughout your facility in high-traffic areas. GenFuel eliminates making lift trucks drive out of the way to charge or change their batteries.

Boost labor efficiency. A WMS can help direct employees regarding which tasks to complete next and the best ways to get through the next task efficiently.

The GenKey enhancement: Nothing boosts efficiency like trucks that operate at full power for an entire shift. By empowering your employees with GenDrive-powered vehicles, efficiency and productivity can be improved by 10-15%.

Predictability of fleet movement can now be measured in dollars. Because fuel cells guarantee constant, consistent power to the vehicle, truck operators can now be properly allocated and activities can be streamlined. Labor dedicated to changing batteries is now more efficiently utilized somewhere else in the facility.

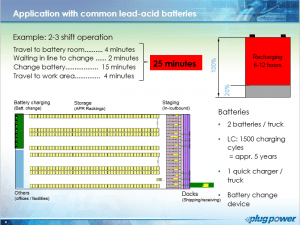

A battery change, which can take approximately 15 minutes, is now replaced by a refueling that is completed in as little as 60 seconds. This recaptured time, in a 100 truck fleet,  operating three shifts a day for 360 days, represents more than 25,000 hours each year that can now be put back into the business as a more productive workforce.

operating three shifts a day for 360 days, represents more than 25,000 hours each year that can now be put back into the business as a more productive workforce.

Based on proven customer data and performance improvements, Plug Power certainly recommends using a WMS in conjunction with adopting fuel cells in a DC facility in order to enhance the benefits that come from more efficient DC operations.

Reigning in forklift costs is crucial to reducing costs, energy waste and environmental impact in any facility. In addition to adjusting routes or optimizing the number of forklifts running throughout the facility, implementing fuel cells as an alternative power source can be incredibly beneficial.

Fuel cells fit seamlessly into forklifts and other material handling trucks, require a downtime of as little as one minutes to refuel and deliver consistent performance even when refueling is imminent. Fuel cells increase productivity, reduce the need for large battery charging rooms and help keep your facility environmentally friendly.

For more information on Plug Power’s GenKey fuel cell hydrogen and service solution, visit https://www.plugpower.com.