Fuel Cell Efficiency 101: The Key Metrics

Many view energy efficiency as the golden goose, or something to put at the center of production, procurement, and value-chain planning. Efficiency, after all, is almost universally viewed as an accolade and something to which to aspire going far beyond the world of energy.

Who wouldn’t want to be more efficient? And, indeed, energy efficiency is important.

Few would choose a refrigerator from the 1990s today, for example, given how much more efficient the devices have become decades later. Dollars and commonsense (pun intended) speak here: An energy-efficient refrigerator means lower consumer and business electricity bill expenses. As another case in point, many choose sedans over sports utility vehicles and large pick-up trucks for much the same rationale.

Yet, voyage beyond mere black and white case studies and energy efficiency — in of itself — is not such a cut and dry issue. We all use items to make our lives more efficient. For example, cell phones made our lives more efficient because we could call someone right away. Now, we have smart phones and smart watches that make our busy lives even easier to manage.

The same goes for fuel cell efficiency. In actuality, energy efficiency and hydrogen fuel cell efficiency are among multiple metrics that are key to consider when building out energy portfolios, mapping out energy procurement plans, or making consumer choices.

And three of those metrics, we believe, sit at an even greater level of particular importance: productivity, robustness, and sustainability.

Why these? That starts with a set of additional framework questions.

For one, are hydrogen fuel cells efficient? Secondly, how does fuel cell technology boost productivity? Further, what is the robustness of a fuel cell? And then just how sustainable are fuel cells?

As a global green hydrogen fuel cells sector leader, Plug sits uniquely positioned to answer these questions, with technological solutions responding to them. Before tackling that, however — or as additive supplemental reading — check out our previous blog posts offering the basics of hydrogen and a 101 on fuel cells.

How Fuel Cells Boost Productivity

Having many ants in a colony yields great efficiency levels. But what does that have to do with hydrogen fuel cells of the sort utilized by Plug across multiple applications? In short, advantages inherent to the Proton Exchange Membrane (PEM) fuel cells technology itself.

But first, we must address the issue of fuel cell efficiency head-on.

Commonly, fuel cell technology detractors point to the comparative efficiency advantage lithium ion batteries possess. PEM fuel cells, Plug’s technology of choice, average about 40 to 60% efficiency. Combustion engines, by contrast, only average 20% to 35% efficiency in powering cars.

As the U.S. Department of Energy has stated, “Fuel cells are the most energy efficient devices for extracting power from fuels.”

So, PEM fuel cells’ efficiency comes out a clear winner over internal combustion engines. That said, lithium ion batteries are actually 90% efficient and lead acid batteries produce efficiency comparable to PEM fuel cells at a level of 50%.

Yet, looking at efficiency in fuel cells alone in this instance leads to misleading conclusions.

Why? As detailed in our fuel cells applications blog, one major issue with battery technology is that it requires frequent recharging. And recharging takes time. A lot of time. To cite the old adage: time is money and productivity pays off.

By contrast, hydrogen not only lasts longer on a miles per measured unit basis, but also takes far less time when the time for refueling comes. How much shorter?

First, take range. The U.S. Department of Energy points out that in 2021, battery-powered electric vehicles averaged a range of 234 miles and The Washington Postrecently reported that to get to an 80% “fast charge” takes between 20 minutes to an hour. The Energy Department’s Alternative Fuels Data Center, in juxtaposition, has pointed out that “Similar to conventional internal combustion engine vehicles, [fuel cell vehicles] can fuel in less than 4 minutes and have a driving range over 300 miles.”

Hydrogen fuel cells, generally speaking, run up to twice as long per fill-up in devices compared to battery-powered ones.

Additionally, those using fuel cells within warehouses in machinery such as forklifts report seeing productivity rises of up to 15%. And where battery-powered forklifts see their speeds diminish 14% during the last half of the battery charge, Plug’s GenDrive fuel cells persist at full power until refueling needs arise. This includes freezer applications, in which Plug’s fuel cells can function within temperature zones dipping as low as -22°F. This is a situation for which batteries, for their part, are known to go kaput or at the least see performances drop between 25% and 50%.

This all means, put simply, more time available to deliver packages and other goods. It also means greater productivity on the warehouse floor for materials handling, where our fuel cell technology currently helps propel operations of companies such as Walmart, Amazon, and other Plug partners.

For an example of efficiency in action, enter FreezPak.

A frozen foods warehousing and logistics company, FreezPak told Plug at its 2022 Symposium that it has saved 31.5% in electricity since beginning its partnership with Plug in 2014. Those costs previously arose for FreezPak in facilitating on-site battery charging. While swapping batteries can take up to 15 to 20 minutes per battery, refueling hydrogen fuel cells takes less than three minutes.

The Plug-FreezPak partnership, with Plug set to provide hydrogen fuel cells, hydrogen fuel and fueling stations at 11 U.S. FreezPak sites for 400 PEM fuel cells-powered forklifts in the years ahead, also helped FreezPak to gain 5,000 to 10,000 square feet per facility because they no longer have to store forklift batteries in-house for repetitious replacement.

Trade press reported that the switchover to hydrogen fuel cells for the company’s forklift fleet has garnered “a 100% improvement in productivity” for FreezPak.

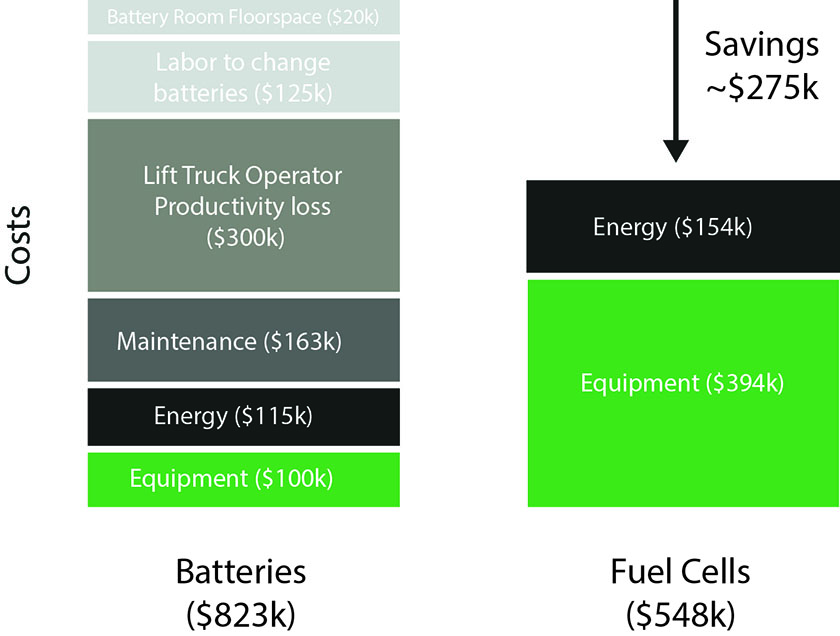

For a summary of the warehouse economic productivity benefits of 50 fuel cell-powered forklifts over a 10-year period compared to 50 lead battery powered forklifts, see the graphic below.

Fuel cells, as these examples exhibit, spend more time moving products and less time at-rest refueling. Meaning, in the grander scheme of things, one could even consider them more efficient at actually getting work done.

That’s all mobility-related, however. What about stationary power production?

For stationary power, for which Plug’s GenSure fuel cell products have provided backup power within the telecommunications industry for companies such as AT&T and Southern Linc. a similar story plays out on efficiency versus productivity. While diesel generators may be more common, fuel cells have proven to, not only be efficient, but better for the environment.

In life as in energy availability, things do not always go the way we hope.

With capital-intensive business decisions on the line, in fact, it is important to plan in advance for when things could and do go wrong. Given power outages do not always last for seconds and sometimes can last days or weeks, it is all the more important to have a cost-effective contingency plan in place. If, or rather when that happens, Plug can serve as a key partner during times of grid duress.

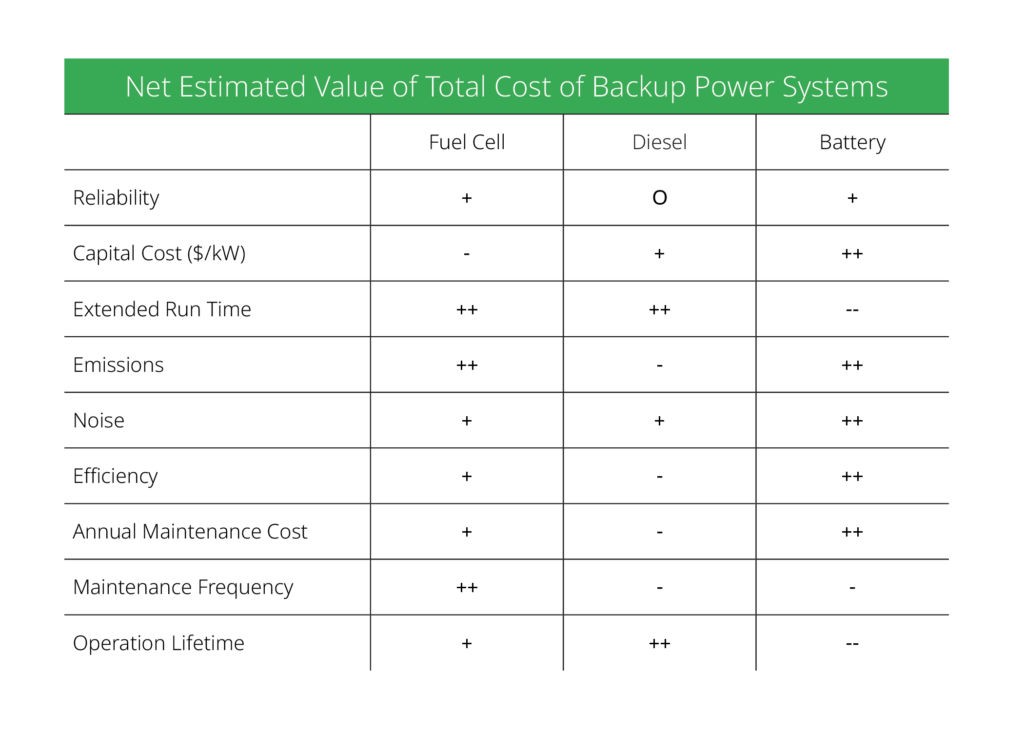

Directly to that point, the National Renewable Energy Laboratory (NREL) has concluded that “for durations above 12 hours, hydrogen has an economic advantage over batteries.” The U.S. Energy Department has also concurred that hydrogen fuel cells for backup power require a less frequent maintenance need, have a more extended runtime, and a longer operational lifecycle, as summarized in the agency’s chart below.

How Robust Are Fuel Cells?

Robustness directly relates to the issue of productivity, with the two going hand-in-hand.

Succinctly, robustness is a metric centering upon design delivering the goods on product longevity and productivity.

Using a real-world nature example, one single ant can only do a small sliver of its colony’s work. But when each ant does a bit of work, it adds up to a highly productive colony. That the species has prevailed for time immemorial speaks for itself in terms of the importance of being robust. This also points to productivity and robustness working as a hand-in-glove relationship.

In the human world, too, one could hire a highly efficient worker to clean a building and give that person extra hours due to their hasty ability to make an office spotless. Yet eventually, that overworked person could run out of energy and their productivity could resultantly plummet.

For Plug and our relationship to robustness, we concurrently maintain an intricate focus on finding a “sweet spot” to ensure fuel cells do not become overtaxed. This relates to productivity again, exhibiting how the two metrics intertwine and undergird our market value proposition.

In layman’s terms, Plug’s engineers constantly tinker with and test our fuel cell technology at a wide range of power inputs and outputs. In collecting that testing data, they have thus far determined that while our fuel cells can technically deliver higher power as a matter of pure engineering prowess, when they go for broke, their longevity — and thus productivity — suffers.

Instead of pushing the red line of what a fuel cell can do as a matter of physics and thermodynamics, our engineers have instead narrowed their gaze on optimized operational productivity zones, determining that this also has promoted a longer product life.

So, to use the metaphor once more: longer product life means less maintenance, more time to do productive work and deliver products to customers, and thus — yes — more money at the end of the day.

How Sustainable Are Fuel Cells?

If efficiency were the only thing that mattered, a 100% shift to battery-powered vehicles and power generation would be called for with few questions asked. But, as already noted, decisions around energy procurement and production entail many additional factors and batteries do not make sense in all use cases.

Multiple options, in other words, make sense because lacking an “all of the above” paradigm reduces choices and consequentially maximizes stakeholder pushback. At this point then, batteries, combustion engines, and green hydrogen fuel cells all make sense in disparate dimensions. There is no “one size fits all” paradigm at-play.

In that exact vein, the investment bank Goldman Sachs has projected that green hydrogen could supply up to 25% of the world’s energy needs by 2050. That means, yes, energy sources of all varieties will still be produced and marketed in bountiful supplies by mid-century. Still, the 25% figure will prove instrumental in moving the dial closer to goals put forward by the United Nations, namely a goal of “net zero” emissions by that date.

Given these dynamics, today it appears likely that passenger vehicles may stand more well-suited to be driven by lithium ion battery power. That’s because, on average, passenger vehicle drivers spend less time on the road. Given that, they require — generally speaking — only one long battery recharge session per day after coming home from work or tending to day-to-day activities and life necessities.

By contrast, delivery van fleets — a market in which Plug has involvement vis-a-vis its partnerships with companies such as Renault, which utilize our ProGen fuel cells — undergo far higher mileage demands as a matter of daily business as they move demanded products from point to point. The same goes for heavy-duty, long-haul vehicles, which Plug can also propel with its ProGen fuel cell technology. In sum, the further range and far shorter refueling time fuel cells offer serves them well.

To reexamine stationary power once more, in areas of the world with high levels of grid reliability and short-lived outages measured merely in seconds or minutes, battery backup power may serve as an apt standby option. But that is a short-term solution, which doesn’t help when power outages can last days if not weeks.

In those cases, fuel cells working in conjunction with a smaller battery plant make more practical sense because reducing emissions while having reliable energy is key. The Energy for Growth Hub, a consortium of university researchers on the issue of energy insecurity, concludes that “the number of people without access to reliable electricity services is over 3.5 billion.”

Beyond the grid and looking at data centers once more as a key strategic industry reliant upon a steady 24/7 dose of energy for its operations, the amount of power production required is too big for batteries at the moment.

Instead, natural gas and diesel power sit at the moment as the incumbent energy resources for powering data centers, given their proven ability to generate the vast amounts of energy needed to keep data servers humming when emergency circumstances arise. Yet, both diesel and natural gas are fossil fuels, posing threats to the planet due to their respective greenhouse gas emissions footprints.

By contrast, Plug’s green hydrogen can enable customers to meet climate goals in this vastly growing sector and at the same time serve as a reliable source of backup power during electricity outages. Such moments are set to become all the more common in the age of the climate crisis due to a rise in extreme weather events and extreme temperature days.

How Plug Has Led the Fuel Cell Industry

In areas ranging from materials handling in warehouses, airport logistics vehicle fleets, the “last mile” delivery market, backup electricity generation, and more, Plug has served as the integrated global leader in fuel cell applications. Plug’s fuel cells currently power sites around the world and the demand continues to grow.

As customers current and prospective continue to address the energy transition, synthesizing and addressing their climate change mitigation and adaptation plans across the value chain, Plug stands ready to assist in those efforts as it pertains to productivity metrics important to our partners’ bottom lines.

We greatly appreciate your interest in learning about hydrogen fuel cell efficiency, productivity, and the ongoing energy transition! To facilitate an in-depth discussion about where Plug’s fuel cell products fit into your operations, please contact us.