FAQ from potential GenFuel customers

Tags: hydrogen, hydrogen FAQ, hydrogen fuel

Earlier this week, we announced that Plug Power customers have surpassed 10 million hydrogen fills into GenDrive fuel cells using GenFuel hydrogen dispensers…at the rate of 15,000 each day. Today, we’re answering the top questions we receive from professionals considering a switch to hydrogen.

Why hydrogen?

Hydrogen is a clean, safe fuel for fuel cell electric vehicles and many other industrial products. Hydrogen enables societies to move beyond traditional power sources in order to become more productive, more reliable and more sustainable. Hydrogen fuel cells are zero-emission power sources that do not create greenhouse gases or air pollutants. The only exhaust is heat and water vapor.

Is hydrogen safe?

Hydrogen is a safe fuel. Like other fuels we use daily, hydrogen calls for respect and is installed in compliance with appropriate industry codes and standards. In addition to meeting the latest hydrogen fueling regulations, Plug Power storage and dispensing stations offer added safety features to prevent operator errors. More than 10 million fuelings to date have been safely performed by Plug Power customers alone.

What is GenFuel?

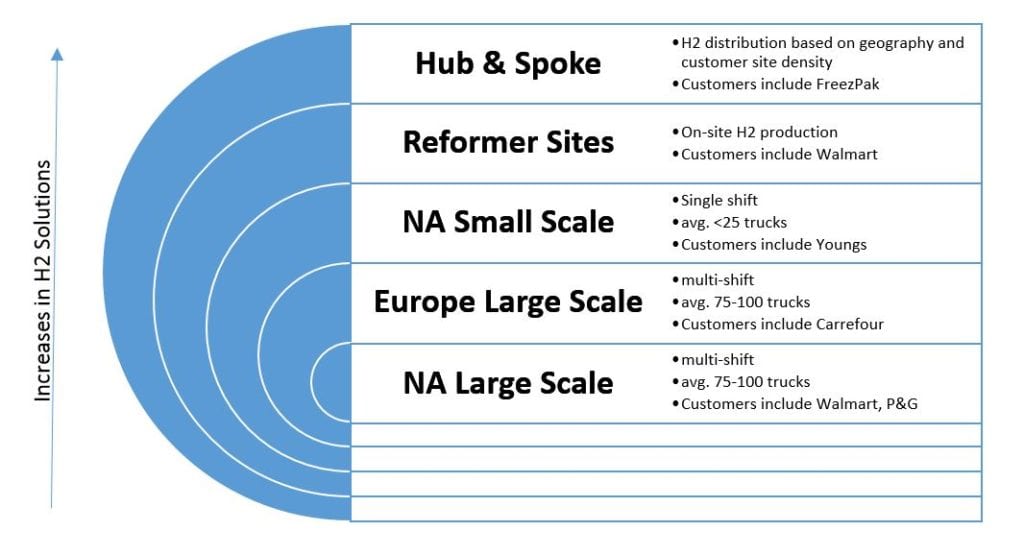

GenFuel is Plug Power’s suite of comprehensive hydrogen fueling solutions, including design, support, commissioning and maintenance – all the components required to successfully dispense hydrogen without disruption to a customer’s operations. GenFuel offerings adapt depending on the size and industry of the customer, as seen in the graphic below. Plug Power also offers GenFuel for stationary power customers. While each solution looks a little different, all of them are focused on providing the best hydrogen storage and fueling offering for each customer application.

What pieces make up a GenFuel hydrogen solution?

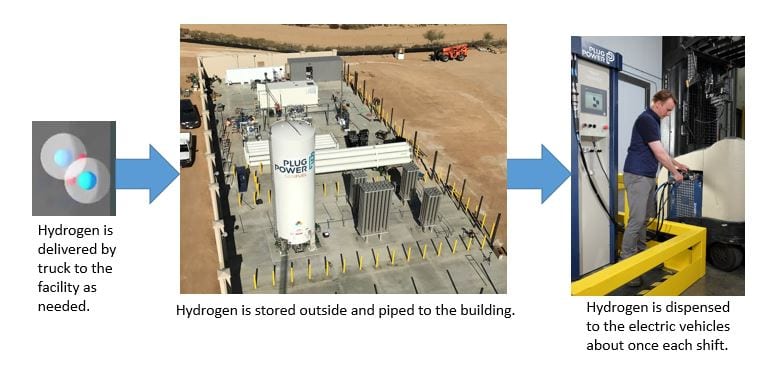

For Plug Power’s largest current markets, the GenFuel hydrogen solution is comprised of three components:

1. Hydrogen Molecule: Plug Power provides hydrogen delivery to customer sites based on customer use – on average, a material handling customer can use 200-300 kg of hydrogen a day. Plug Power leverages quantity buying power to ensure favorable costs to customers.

2. Hydrogen Storage Stations: Hydrogen is stored, compressed and delivered as needed to the facility dispensers using the following components:

-

- Liquid hydrogen storage tank

- Compression system – liquid to gaseous hydrogen

- High pressure hydrogen storage tubes to maximize reserve hydrogen

- Piping for delivering hydrogen into the building, directly to the dispensers

3. GenFuel Dispensers: With its proprietary hydrogen dispensers, fueling a Plug Power motive fuel cell is as simple as fueling a personal vehicle. Plug Power ensures a perfect integration of the fueling system with Plug Power fuel cell products and provides unmatched industrial IoT reporting to help users keep track of their latest performance.

Where is the hydrogen stored?

There are two parts to the hydrogen station. (1) The dispensers where operators refuel their trucks are located near high traffic areas in the facility, enabling operators to quickly, in under 3 minutes, refuel and get back to work. (2) The storage facility is located outdoors, eliminating the need to use valuable real estate inside. That hydrogen is then piped into the building and directly to the dispensers.

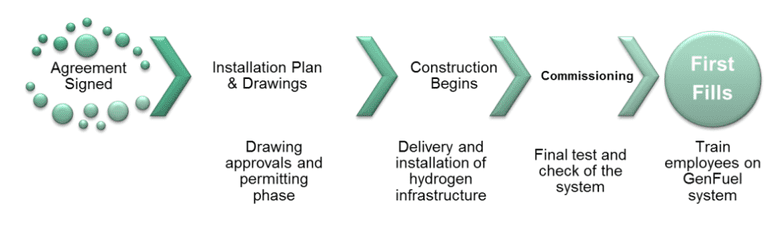

How long does it take to build a hydrogen storage station?

From purchase order to commissioning, a hydrogen facility can take as few as 4 to 5 months to build. Plug Power’s GenFuel infrastructure construction teams include a dedicated project manager, superintendents and in-house mechanical construction division specialized in high-pressure gasses and cryogenics. The Plug Power project manager is a single point of contact for all communications and the key connection to the knowledgeable, highly experienced engineering team that supports all field work. Plug Power manages and directs the entire project’s execution from start to finish – ensuring we deliver high-quality functional hydrogen fueling infrastructure safely in a short period of time. We build cost-effective and high-performance infrastructure across North America every day – so the process is seamless. It’s professional. It’s done properly.

#InfiniteDrive