Delivering Cold-Storage Success with Forklift Fuel Cells

On April 20th, Plug Power and FreezPak Logistics, a leading full-service cold and dry storage facility, co-presented during an hour long webinar about the success of fuel cell power solutions for material handling and other warehouse lift equipment, with an emphasis on the extended benefits for cold storage facilities. The webinar was hosted by NEESC.

The Northeast Electrochemical Energy Storage Cluster (NEESC) is a network of industry, academic, government and non-governmental leaders working together to help businesses that provide energy storage solutions. The cluster is focused on businesses that provide the innovative development, production, promotion and deployment of hydrogen fuels and fuel cells to meet the pressing demand for energy storage solutions.

Chris Tully, Plug Power’s VP Sales Eastern Region, highlighted the business case for fuel cells. He discussed Plug Power’s GenKey “one-stop-shopping” model, including each component: GenDrive fuel cells, GenFuel hydrogen and GenCare customer service.

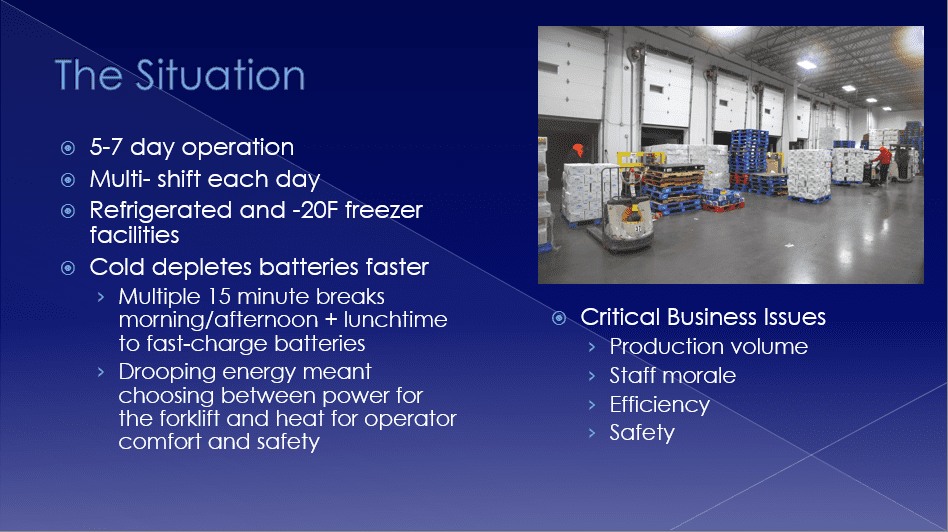

David Saoud, co-President of FreezPak, discussed the specific application of hydrogen and fuel cells within his family’s cold storage warehousing business. With more than 10 million cubic feet of refrigerated and freezer space, FreezPak is a leading frozen food distributor located in New Jersey. And they are 100% Plug Power-fuel cell forklift operated.

Productivity Enhancements Save Money.

Battery charging in the cold warehouse environment was costing FreezPak 1 hour per shift compared to two to four minutes for hydrogen refueling. Over one year, that 60 minutes per shift time savings represented more than 590 hours of gained productivity per forklift truck in a two-shift operation. Fuel cells store enough hydrogen to complete a standard eight- to 10-hour shift, even in the freezer warehouse.

Additionally, FreezPak was able to lower their electric bills by 31.5% after the switch to fuel cells. And, with hydrogen fuel cells, cold chain facilities can eliminate battery rooms, putting both space and capital dollars into business-enhancing activities.

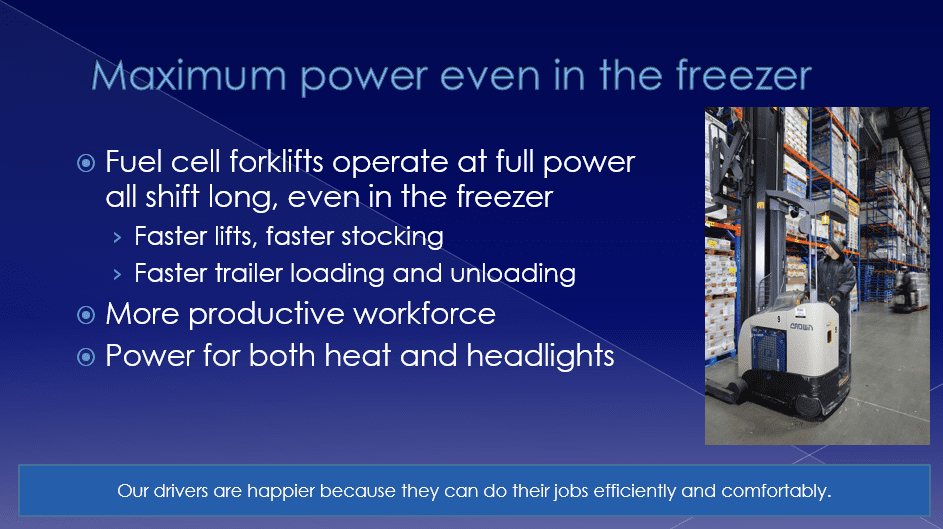

Consistent Power Even in the Freezer.

Unlike batteries, hydrogen-powered forklift trucks operate at full power all shift long, even in the most extreme conditions as low as -22 degrees F. With batteries, FreezPak’s turret truck operators were having to choose not to use their headlights and cab and backrest heaters in order to conserve battery. Imagine driving a car all day in winter without a working heater. The switch to fuel cells not only allows operators to stay productive longer, but also means lift truck operators can remain comfortable and safe in the cold storage facility for a full shift.

To learn more about the cold storage application for hydrogen and fuel cells, listen to the webinar replay here.

Plug Power customers like FreezPak are changing the way the world moves.

#InfiniteDrive